Our signalling solutions developed in collaboration with our customers allow operators to ensure the highest standards in safe, seamless travel with urban and mainline solutions that meet the specific needs of each operation environment.

Smooth rail operations depend on seamless signalling and route control products which offer high availability and reliability. We have the experience of engineering products to comply with all international standards such as CENELEC SIL 0 to 4, and AREMA.

With railway systems becoming ever more complex, railway operators and maintainers need an interlocking system that they can count on to guarantee the performance and availability of the system.

We have had the privilege of working on some of the world's largest cities and countries to meet their mobility needs - rapidly and reliably.

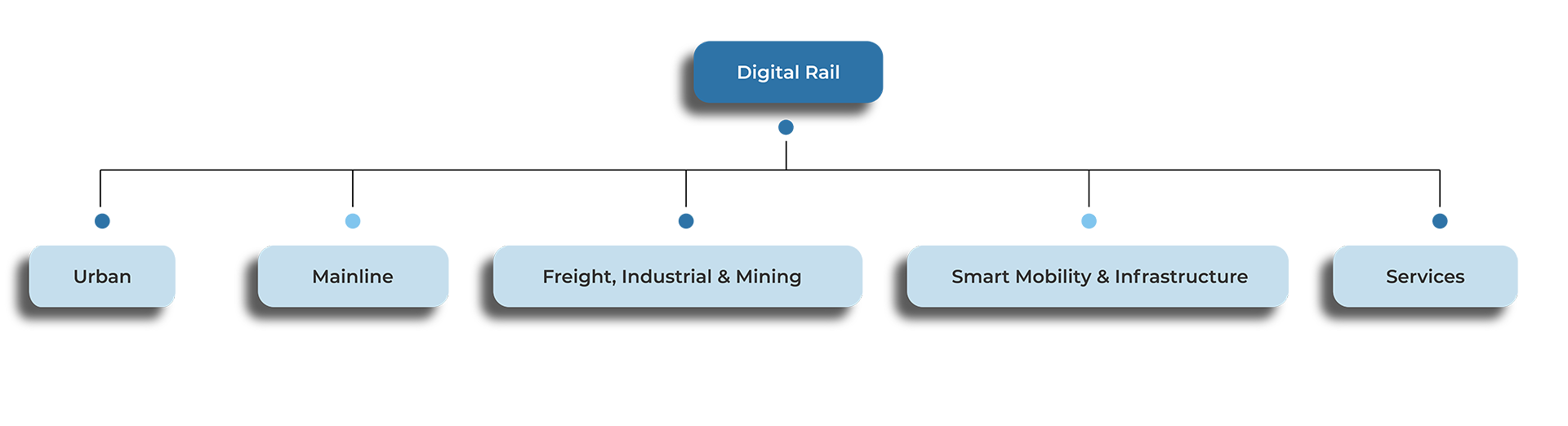

QuEST is experienced in collaborating with customers to meet the demand of signalling solutions across multiple segments. This includes developing signalling solutions for urban and mainline as well as freight and industrial segments. We have a highly capable product engineering team who have worked on a range of technologies including CBTC, ETCS and PTC. We have been partnering with our customers to build signalling solutions for some of the top cities in the world, signalling solutions in vast expansive landscape as well as in industrial and mining environments.

QuEST's product engineering capability covers a range of signalling systems. Our experience in Product Engineering and Lifecycle management helps our customers in the design, development, verification & validation and commissioning phases of multiple systems to improve the operations of rail network to maximize reliability, safety and availability.

Our experienced team of signalling engineers have worked on Automatic Train Control (ATC), Automatic Train Protection (ATP), Automatic Train Operation (ATO) and other critical components of On-board systems including Radios, On-Board Train Communication, HMI and DMI, Online Key Management systems, GRU, etc.

We have the capability to develop and validate signalling software to SIL 4 standards. The scope of product engineering work executed includes Systems Engineering, Software design & development, Component Testing, Sub-system Testing, System Testing (Lab environment), DevOps and Release Management, Configuration management, DMI Test Automation, and HMI Screen development & Testing.

Our teams have collaborated with the customers in the engineering of the various module of the Wayside solutions. This includes Radio block centre, Radio block centre, Train to track communication, Discreet and safe point machines, Train External Communication, Train Radio, communication and network. The scope of work we have undertaken includes Design & Development, S/W Verification & Validation, Development of tools used for Testing and testing of Tools & applications with Wayside controller.

Interlockings ensure safety. They check that rail sections are free, determine routes, and provide information on movement requests and train speeds.

The scope of product engineering work undertaken on trackside equipment includes Engineering work done includes